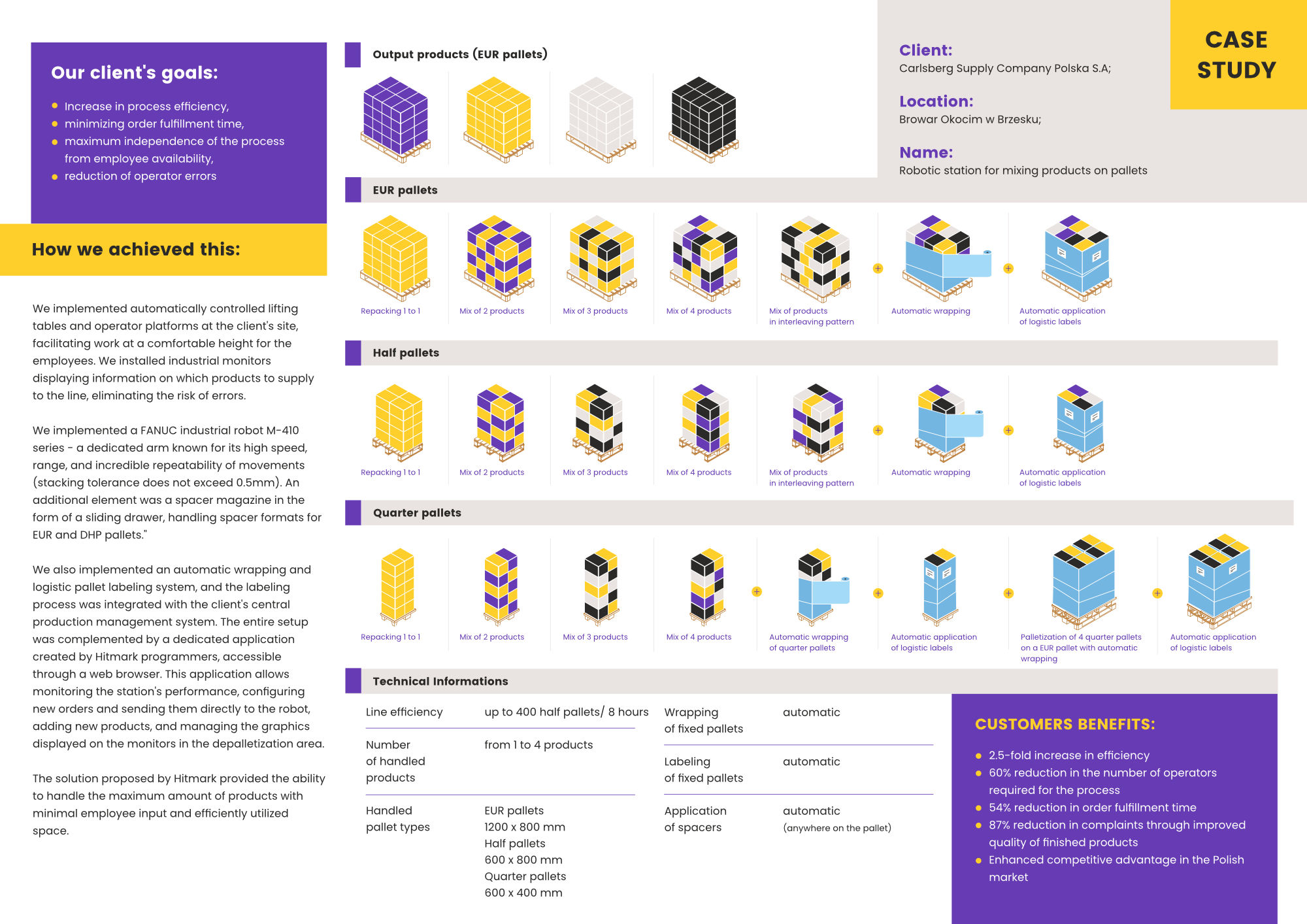

The implementation of a high-speed, long-reach industrial robot with precise repeatability significantly improved the entire process's efficiency while minimizing operator errors. Hitmark’s proposed solution allowed the handling of a maximum number of products with minimal operator involvement and optimized use of available space.

Product mixing and palletizing at Okocim Brewery in Brzesko