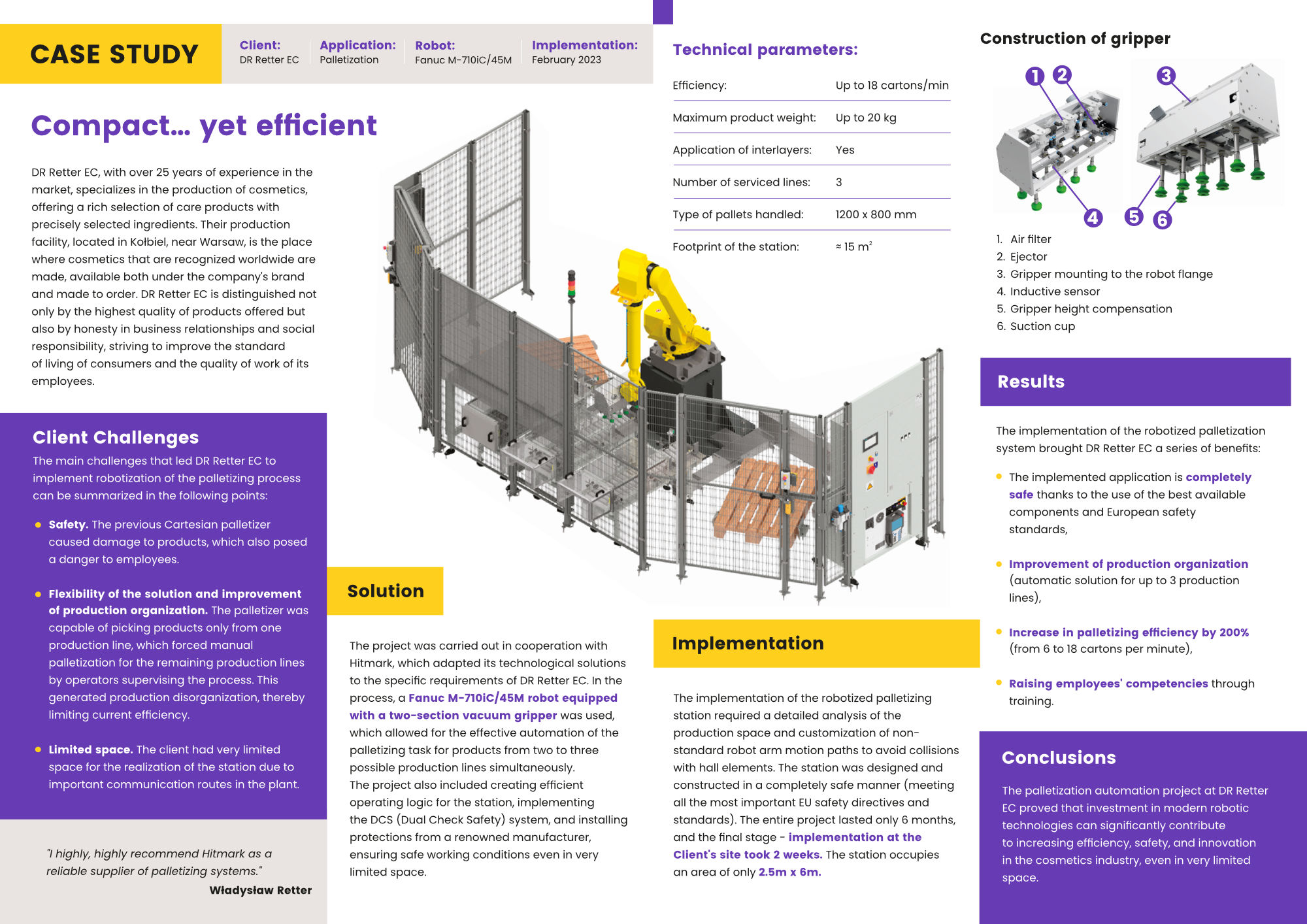

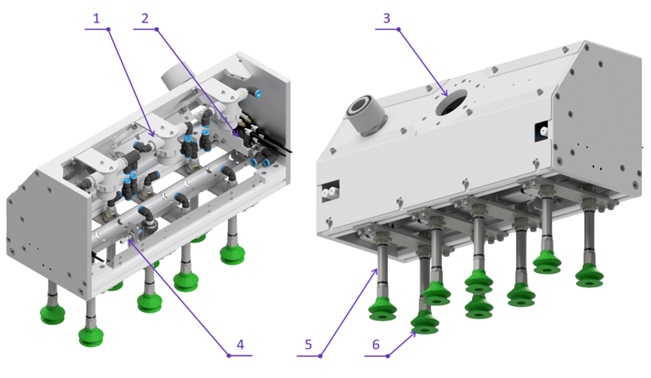

A Fanuc M-710iC/45M robot equipped with a dual-section vacuum gripper enabled product palletizing from up to three production lines simultaneously. With top-tier safety systems including Dual Check Safety and space-optimized installation, this solution provided high productivity and operational safety in a confined production space.