Using high-performance Fanuc robots, pallet and product buffers, this automated line replaced manual tasks, boosting output fivefold. The automated system handles depalletizing, packaging, and palletizing with minimal operator input and maximum efficiency.

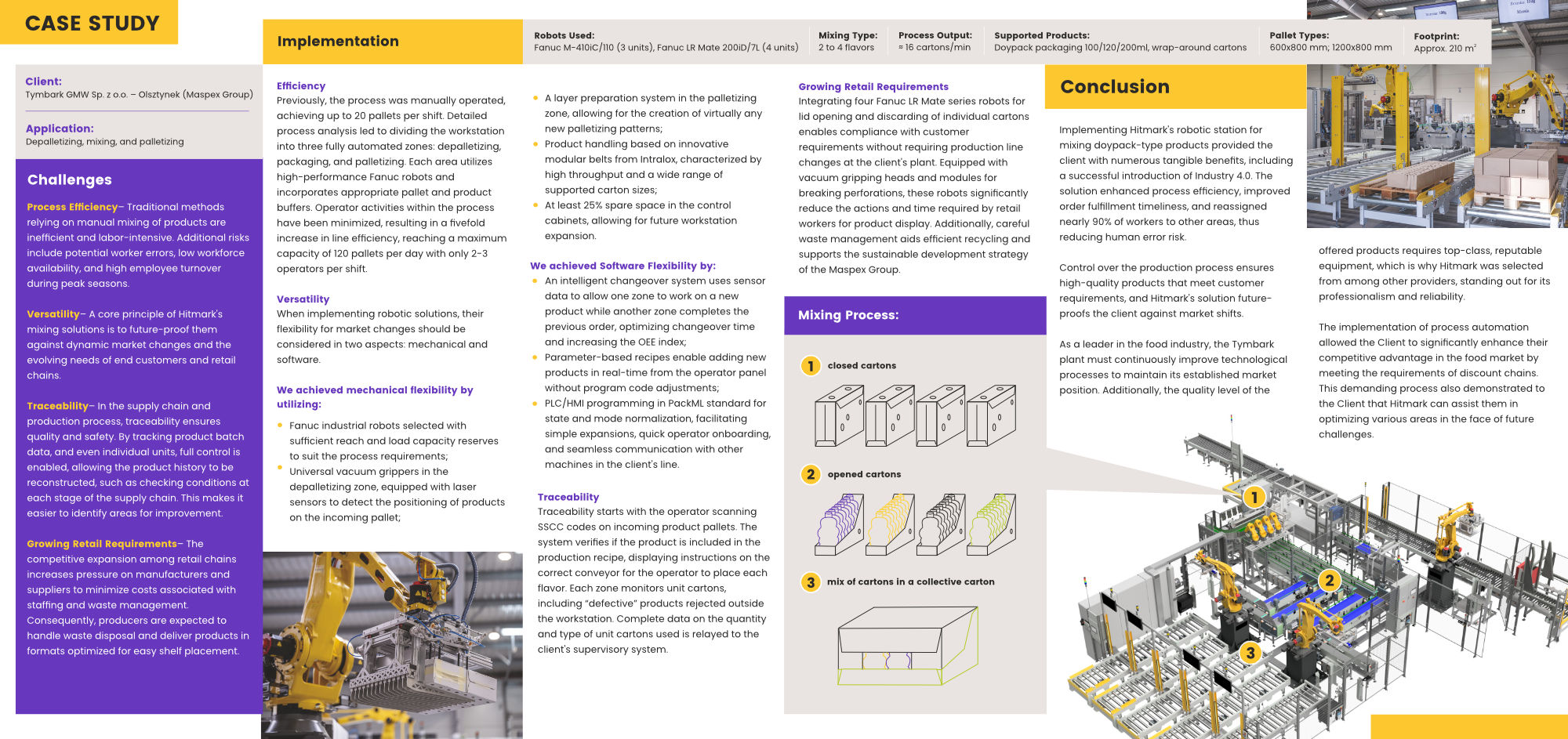

Robotic mixing of doypack-type products