In the world of modern industrial automation, collaboration with OEMs (Original Equipment Manufacturers) plays a critical role in creating efficient and scalable solutions. System integrators, machine manufacturers, and production companies increasingly rely on proven components and technologies provided by reputable OEMs.

Example of Collaboration – Palletizing with Fanuc Robots

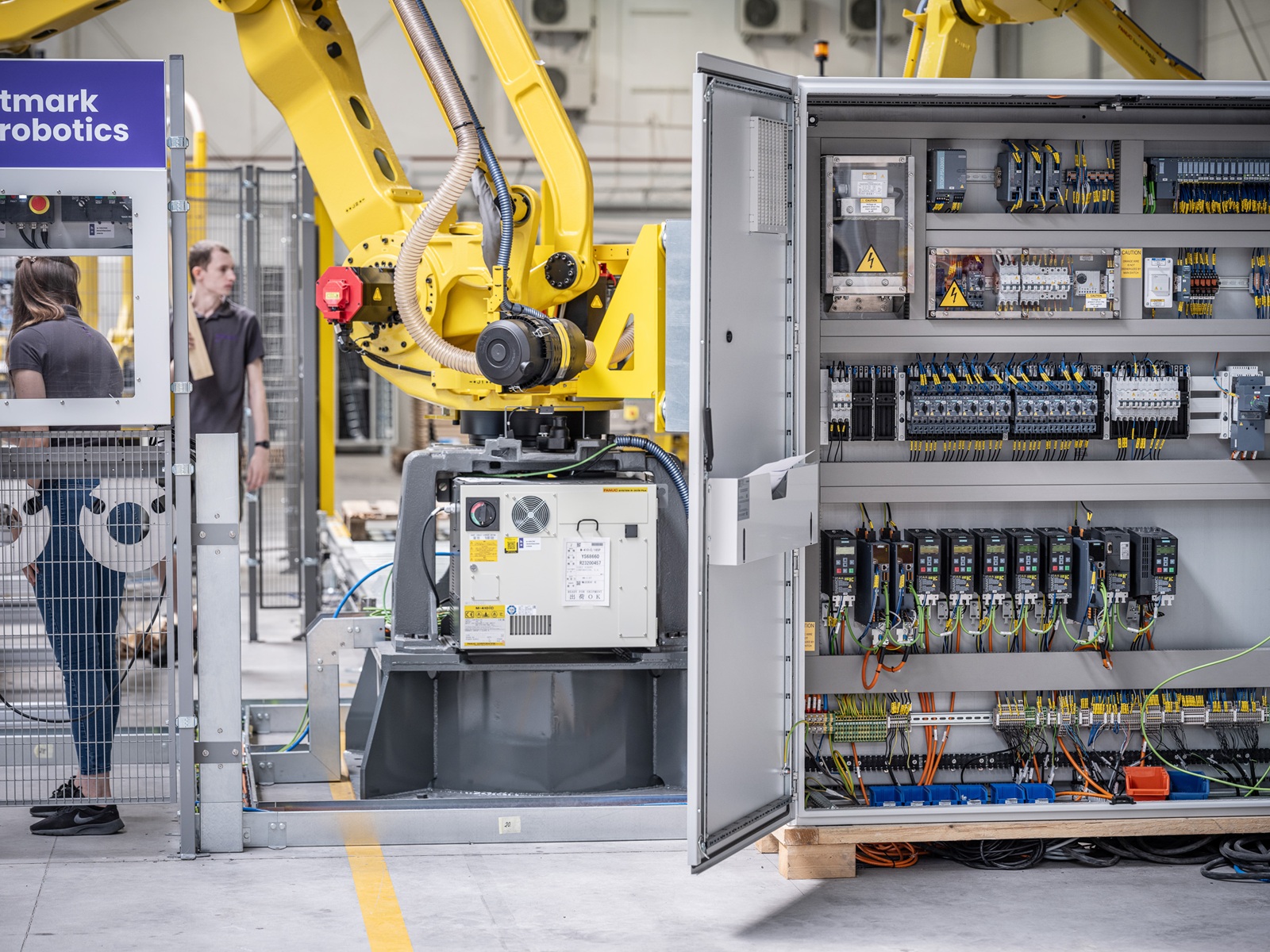

In the field of robotic station integration, including palletizing systems, reliable industrial robots are a key component. By collaborating with a Fanuc robot integrator, such as Hitmark, OEMs can leverage advanced technologies that ensure precision, speed, and process repeatability. Pre-developed control algorithms, a wide range of robot models, and technical support allow for the efficient customization of systems to meet client needs.

OEM Collaboration with Fanuc Robot Integrators – Benefits for Your Business

In the rapidly evolving world of production automation, OEMs strive to deliver increasingly advanced and comprehensive solutions to their clients. Collaborating with an experienced Fanuc robot integrator, such as our company, opens new possibilities for machine manufacturers in areas like palletizing, depalletizing, and advanced product mixing at the end of production lines.

Benefits for OEMs from Partnering with Us

- Enhanced Offerings with Comprehensive and Innovative Solutions

As a Fanuc robot integrator, we deliver advanced systems for automating final production stages, seamlessly integrating with OEM machines. This enables your company to offer ready-to-deploy solutions, increasing their appeal to end customers. - Increased Market Competitiveness

OEMs that integrate our palletizing and depalletizing systems stand out from the competition by delivering more versatile and efficient production solutions. Automation of final production processes enhances productivity and eliminates human error, providing a strong selling point for clients. - Access to Our Expertise and Experience

We collaborate with renowned manufacturers across various industries and have a broad client base, making us a trusted business partner. We stay up to date with the latest automation trends and share our knowledge to help OEMs tailor solutions to even the most demanding production processes. - Technical Support and Reliable Service

We provide full support at every stage of collaboration—from technical consulting and implementation to system servicing and optimization. Our team of specialists is available 24/7, minimizing downtime risks and maximizing production efficiency. - Opportunity to Reach a Wide Client Base

As a company working with numerous industrial facilities and integrating Fanuc robots across various sectors, we can assist OEMs in establishing connections with new clients. Our network includes nearly 1,500 production plants and 20,000 potential customers, offering real opportunities to expand market reach.

Applications of Our Systems in OEM Solutions

- Palletizing – Automated stacking of cartons, bags, or other packages on pallets, optimizing logistics and reducing labor costs.

- Depalletizing – Fast and precise unloading of pallets, ideal for distribution centers and processing plants.

- Product Mixing – Advanced solutions for dynamically combining different types of products at the end of production lines, enabling greater production flexibility and customization for individual client orders.

Collaboration with OEMs in industrial automation is key to efficiency and market competitiveness. By integrating advanced systems such as Fanuc robotic arms, machine manufacturers can offer more comprehensive and innovative solutions. The benefits include increased competitiveness, access to expert knowledge, reliable technical support, and the ability to reach a broad customer base. Automating processes like palletizing, depalletizing, and product mixing significantly optimizes production, reduces costs, and improves process quality and repeatability.