Industry 5.0 is not just another stage of automation – it's a new model in which humans and technology work together to create intelligent, sustainable, and flexible production environments. Discover how to harness this potential in practice and prepare your company for the future...

The evolution of industry has driven technological, social, and economic change for centuries. From the steam revolution (Industry 1.0), through electrification and mass production (Industry 2.0), digitization and automation (Industry 3.0), to the integration of IT systems with machines (Industry 4.0), each industrial era has transformed how we create value.

Today, we’re entering a new chapter – Industry 5.0. Rather than simply continuing the trend of digital transformation, it marks a shift toward humanizing technology. While Industry 4.0 focused on integrating machines and data, Industry 5.0 puts the human back at the center of the production process. It envisions a harmonious collaboration between people and intelligent systems, where technology supports – rather than replaces – human capabilities.

According to the European Commission and national institutions like the Polish Agency for Enterprise Development (PARP), the fifth industrial revolution aims to build a more resilient, sustainable, and inclusive economy by emphasizing innovation, production personalization, and social responsibility. Collaborative robots (cobots) play a key role, enabling safe and effective real-time cooperation between humans and machines.

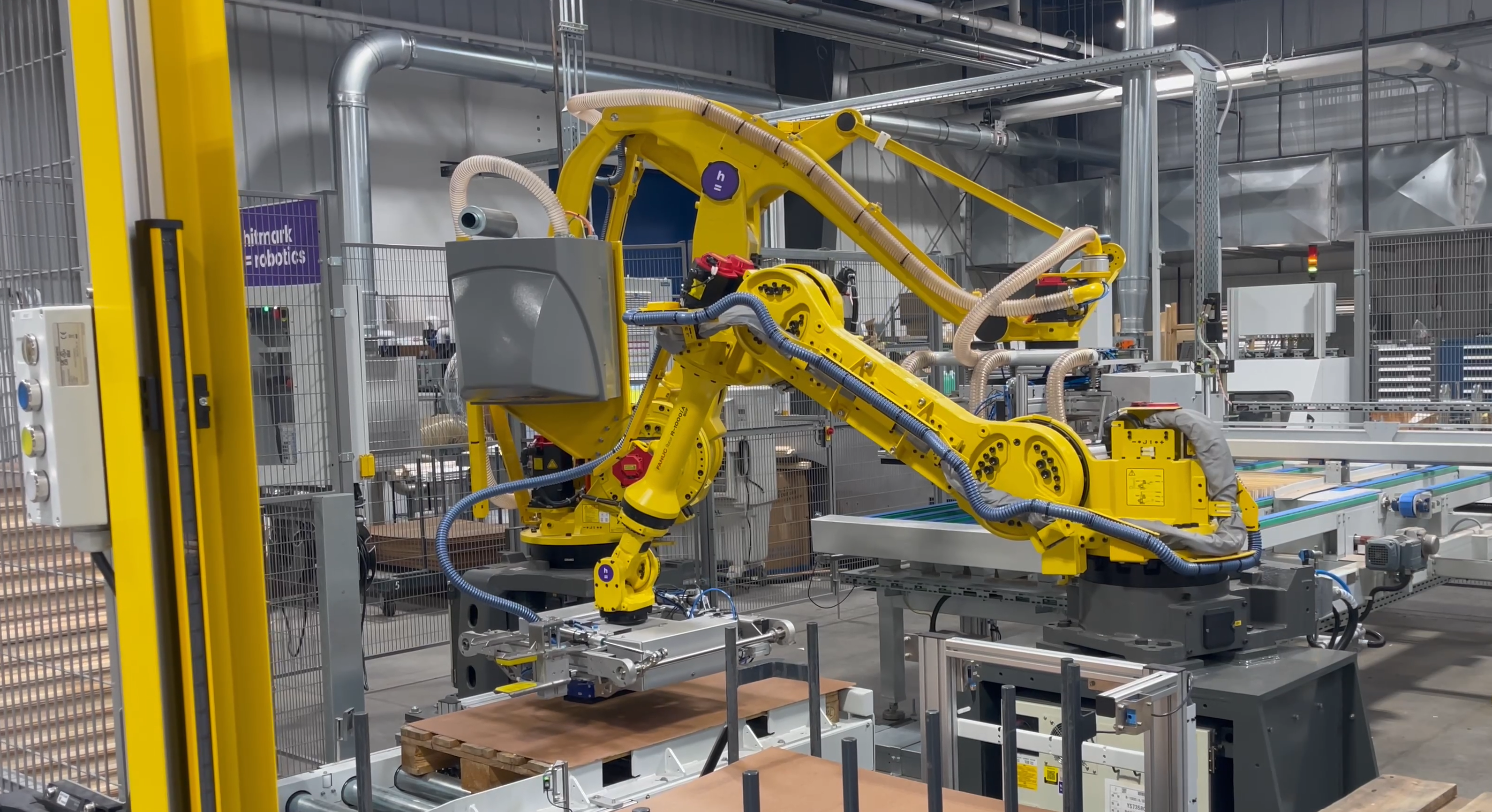

Industry 5.0 is not a futuristic vision – it’s a reality being implemented today. Companies like Hitmark Robotics are already supporting the industrial transformation toward a smarter and more human-centric operational model.

The fourth industrial revolution – Industry 4.0 – was centered on automation, digitization, and the integration of production systems. Technologies such as the Internet of Things (IoT), artificial intelligence (AI), cyber-physical systems, and Big Data analytics enabled the creation of smart factories capable of autonomous operation and real-time responsiveness.

Despite these advances, Industry 4.0 primarily focused on process efficiency and cost reduction, often minimizing the role of the human operator. Machines took over more tasks, and people became supervisors of automated systems.

Industry 5.0 is a natural evolution – but with a completely new focus. It brings humans back into the spotlight. This approach meets the need for a more balanced, flexible, and personalized production model. The aim is not to replace people with machines, but to create work environments where humans and technology complement each other’s strengths.

Key differences between Industry 4.0 and 5.0:

This is not just a technical shift – it's a new philosophy of industrial operations that considers employee well-being, environmental impact, and customer needs as central priorities.

Core Principles of Industry 5.0

Industry 5.0 is a new production paradigm where technology doesn't replace humans – it works alongside them. At its heart is the worker – their knowledge, creativity, needs, and safety. This human-centric approach is what sets the fifth industrial revolution apart from previous phases.

Humans at the Center of the Production Process

As outlined by the European Commission and national digital transformation programs, the human role in Industry 5.0 is fundamental. Production systems are designed not only for efficiency but also for ergonomics, well-being, and skills development.

Technologies such as collaborative robots (cobots), smart interfaces, and augmented reality (AR) enable people to work in integrated environments where humans make decisions and machines assist, automate, and relieve physical strain.

Product and Service Personalization

Unlike the mass production typical of earlier industrial eras, Industry 5.0 supports flexible manufacturing tailored to individual customer needs. With advanced digital technologies like 3D printing, online configurators, and digital twins, companies can create short, customized production runs without sacrificing efficiency.

This production model increases customer engagement and market differentiation while maintaining high levels of automation and quality.

Sustainable Development and Environmental Responsibility

Industry 5.0 also responds to global environmental challenges. One of its pillars is sustainable development – focused on reducing resource consumption, minimizing CO₂ emissions, and designing eco-friendly systems.

New technologies enable precise monitoring of energy use, process optimization for energy efficiency, and waste reduction. These efforts are supported by public institutions and EU initiatives such as the Green Deal and the industrial digital transformation strategy.

Industry 5.0 is built on the synergy between humans and technology. Solutions are designed not just for automation, but to enhance human capabilities while respecting the environment and social context. Here are the technologies that form the foundation of this new industrial era:

Got a question? Write to us at: hitmark@hitmark.pl