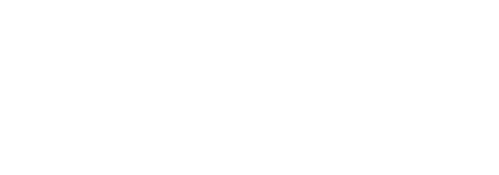

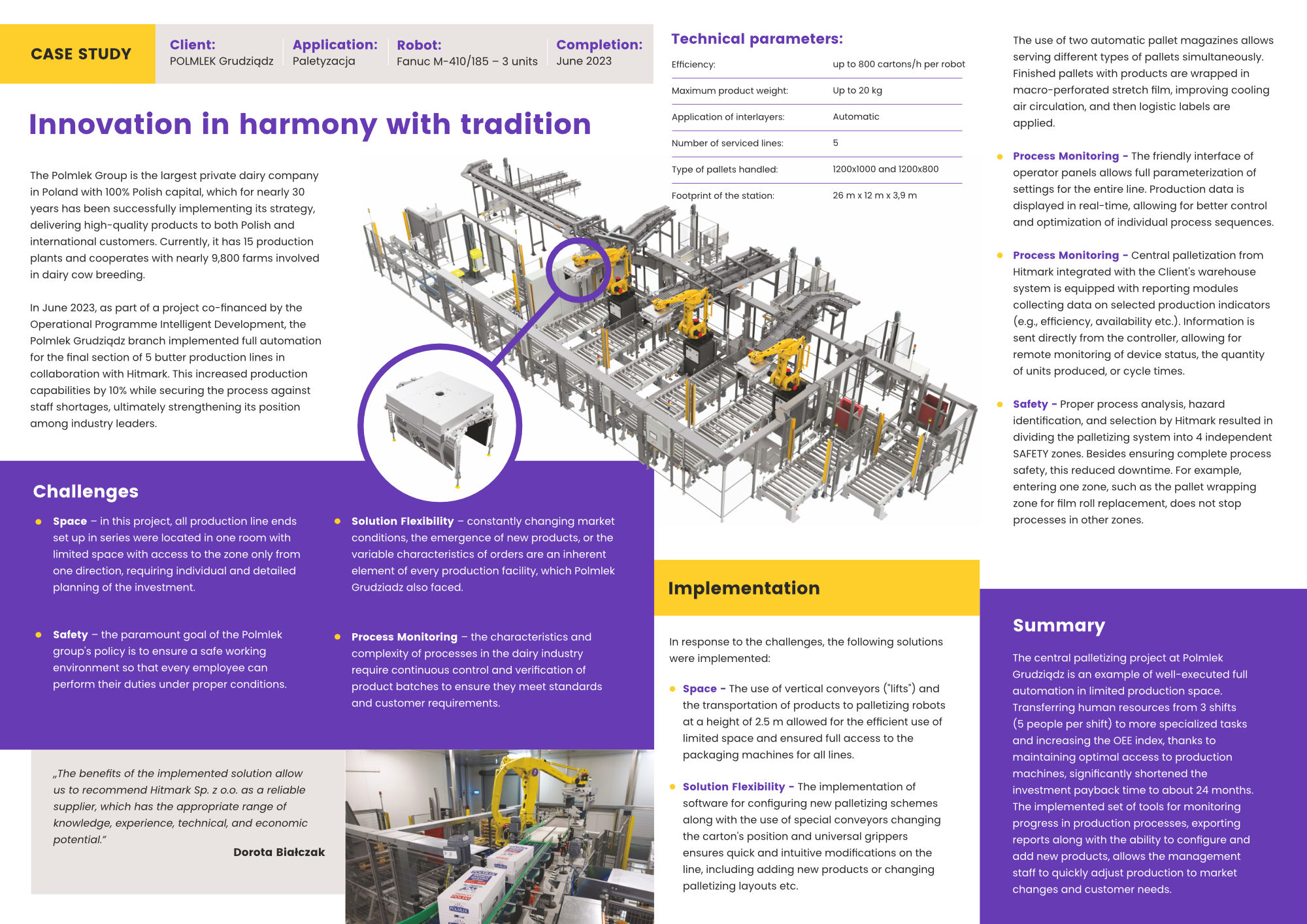

The central palletizing project at Polmlek Grudziądz is a well-designed automation solution tailored to the client’s needs. Key features included elevators and overhead transport at 2.5 meters, maximizing limited space. Configurable palletizing schemes and production monitoring tools ensured flexibility, transparency, and efficiency, with high-quality components minimizing downtime.

Robotic butter palletizing station