A joint solution by Hitmark Robotics and Bosch Rexroth is a direct response to the growing need for automation and increased palletizing efficiency in the food industry.

Modern production automation is not only about efficiency, but also about precision and delicacy in product handling. The food sector—due to its specific requirements, including the need to maintain the highest standards of cleanliness and safety—increasingly seeks solutions that combine high efficiency with strict hygiene standards and careful product handling.

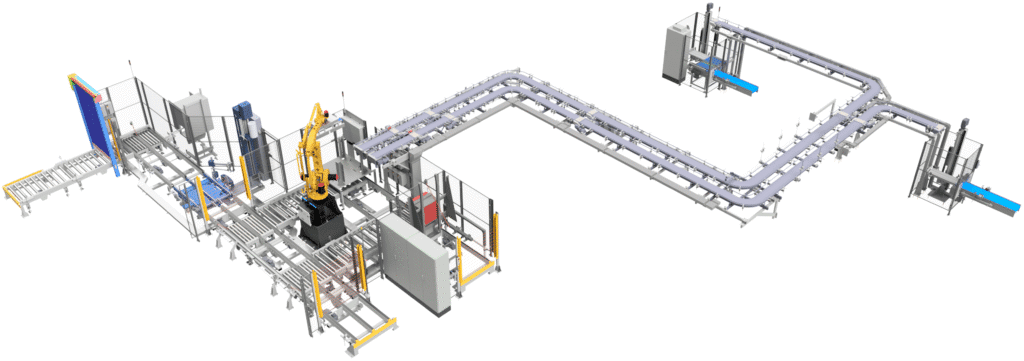

A perfect example of such an approach is a project delivered by Hitmark Robotics in cooperation with Bosch Rexroth—a modern palletizing line for dairy products. Both companies are committed to providing efficient and reliable automation. By combining experience, technology, and a shared vision, they have developed an application that genuinely supports modern FMCG production lines.

The application features the reliable VarioFlow 320 smooth chain conveyor system from Bosch Rexroth.

VarioFlow is a modern and quiet modular chain conveyor system that excels at transporting light and medium loads. It offers exceptional flexibility—universal drive heads with modular drive units allow free selection of the motor mounting position.

Thanks to its low-friction design, the system enables the creation of long conveyor sections powered by a single drive, resulting in reduced wear, shorter downtimes, lower operating costs, and extended service life.

The system is available in a wide range of aluminum and stainless steel variants, in six widths (from 65 to 320 mm), with seven chain types, and transport speeds of up to 120 m/min.

Designed for the safe transport of delicate products, VarioFlow is ideal for industries such as food, pharmaceuticals, packaging, and electronics. It minimizes the risk of surface damage—a critical factor in the food sector, particularly in dairy processing. The system is perfectly suited for moving a variety of items, regardless of environmental conditions or production specifics. It ensures smooth operation, high reliability, and reduced lead times for logistics tasks.

The application uses the following components:

▶ 10 conveyors with a total length of approx. 57 meters

▶ 10 SEW gearmotors

▶ 10 active transport bridges

▶ A single-stage aluminum strapping system with sliding plastic guides

Hitmark Robotics—an industrial automation integrator—specializes in robot-based automation. The company offers robotic palletizing, depalletizing, and order-picking systems, supported by integrated transport and control solutions.

In this project, Hitmark Robotics’ task was to integrate production machinery with a complete product palletizing system.

The implementation of the automated system has brought significant benefits. Above all, it has greatly reduced the risk of product damage—crucial for fragile dairy products. By elevating the transport line to 2.5 meters, workspace utilization was optimized, while maintaining free movement for staff and transport trolleys.

The line is stable and efficient, and thanks to its modular design, it can be easily expanded or adapted to changing production requirements. Integrated with Hitmark Robotics’ proprietary automation system, it enables continuous monitoring of operating parameters and rapid format or packaging type changes without downtime.

The package preparation process is fully automated, streamlining the entire workflow. The system groups and arranges products according to a predefined pattern, operating with high precision—even in demanding industrial environments.

This solution is a prime example of modern, comprehensive automation that combines Bosch Rexroth’s precise transport technologies with Hitmark Robotics’ intelligent control and integration. Thanks to the well-thought-out line architecture, it ensures gentle handling of delicate products while allowing quick adaptation to changing production demands—without downtime or quality compromises.

It is a clear example of technological synergy that actively supports the growth of the food industry and sets new standards for palletizing process automation.

As one of the world’s leading suppliers of drive and control technologies, Bosch Rexroth ensures the efficient, safe, and reliable operation of machines and systems of any size and purpose. The company combines global expertise in mobile applications, industrial applications, and factory automation.

Through specialized components, customized system solutions, engineering, and services, Bosch Rexroth enables full network integration of applications.

The company offers solutions in hydraulics, electric drives and controls, gear technology, linear motion and assembly technology, as well as software and IoT interfaces.

Its subsidiaries in over 80 countries, employing around 32,600 people, generated sales of €6.5 billion in 2024.

More information: www.boschrexroth.com

The Bosch Group is a leading global supplier of technology and services. It employs around 418,000 associates worldwide (as of December 31, 2024). In 2024, it generated sales of €90.3 billion.

Its operations are divided into four sectors: Mobility, Industrial Technology, Consumer Goods, and Energy and Building Technology.

Bosch aims to use technology to shape global trends such as automation, electrification, digitization, connectivity, and sustainability. Its broad diversification across industries and regions enhances its innovative strength and stability.

With its unmatched expertise in sensor technology, software, and services, Bosch offers customers connected solutions from a single source. The company applies its knowledge in AI and IoT to create user-friendly and sustainable products. Under the “Invented for life” mission, Bosch strives to improve quality of life while conserving natural resources.

The Bosch Group comprises Robert Bosch GmbH and approximately 490 subsidiaries and regional companies in over 60 countries. Including its sales and service partners, Bosch’s manufacturing, engineering, and sales network covers nearly every country in the world. Innovation is the foundation for the company’s continued growth, with around 87,000 associates working in research and development across 136 locations globally.

More information: www.bosch.com, www.bosch-press.com

Reader Contact:

MSc Eng. Jakub Koper

+48 22 738 19 39

jakub.koper@boschrexroth.pl

www.boschrexroth.pl

ul. Jutrzenki 102/104, 02-230 Warsaw

+48 22 738 18 00

info@boschrexroth.pl

www.boschrexroth.pl

Regional Offices:

Bytom: ul. Kędzierzyńska 17a, 41-902 Bytom

+48 32 363 51 00

katowice@boschrexroth.pl

Gdańsk: ul. Azymutalna 9, 80-298 Gdańsk

+48 58 520 89 90

gdansk@boschrexroth.pl

Poznań: ul. Wichrowa 1A, 60-449 Poznań

+48 61 816 77 60

poznan@boschrexroth.pl

Rzeszów: ul. Hoffmanowej 19, 35-016 Rzeszów

+48 17 275 55 00

rzeszow@boschrexroth.pl

Wrocław: ul. Kwiatkowskiego 4, 52-407 Wrocław

+48 71 364 73 20

wroclaw@boschrexroth.pl