Industry 4.0 is no longer an abstract concept from technology reports – it represents real changes occurring in Polish and global companies. More and more enterprises are implementing intelligent solutions, combining automation with data analytics and digital production management. In this part of the article, we explore how Industry 4.0 works in practice across various sectors and how it will develop further to better meet the needs of businesses, markets, and employees.

Also see: Benefits of implementing Industry 4.0 – what will a company gain from digital transformation?

Industry 4.0 is applicable across many sectors of the economy, regardless of the scale of operations. Innovative technologies streamline production, increase flexibility, and allow better adaptation to customer expectations. Below are several examples of how specific industries are utilizing solutions from the fourth industrial revolution.

Automotive Industry: Collaborative Robots on Assembly Lines

The automotive sector has long been a leader in automation. Today, more and more companies are implementing collaborative robots (cobots), which work side by side with humans, performing tasks requiring precision and repeatability. This enables reduced assembly time, improved quality, and alleviates workers from monotonous tasks.

Electronics Industry: Internet of Things for Efficiency

In the electronics sector, IoT plays a crucial role in monitoring devices, predicting failures, and optimizing energy consumption. Sensors installed on machines collect real-time data, allowing continuous control of production parameters and immediate response to any deviations.

FMCG Sector: Personalization of Packaging Using 3D Printing

Companies in the fast-moving consumer goods (FMCG) sector are increasingly adopting 3D printing to create limited edition products, personalized packaging, or production tools. This not only helps stand out from the competition but also better addresses consumers' individual needs without increasing costs.

Pharmaceutical Industry: Digital Supervision of the Supply Chain

In the pharmaceutical sector, Industry 4.0 enables precise tracking of raw materials and products at every stage of production and distribution. Solutions such as blockchain, IoT, and advanced data analytics enhance safety, regulatory compliance, and transparency throughout the supply chain – from the laboratory to the pharmacy.

Digital transformation in industry shows no signs of slowing down – on the contrary, the coming years will bring even faster technological changes and the evolution of business models. Industry 4.0 is no longer a vision of the future – it is becoming a new standard that will deepen with the development of analytical tools, artificial intelligence, and autonomous production systems.

Development of Industry 4.0 Technologies – What’s Ahead?

Experts predict that in the coming years, key innovations will emerge in areas such as:

These technologies will serve as the foundation for even smarter, more automated, and reliable production systems.

Changes in the Job Market and New Competencies

The fourth industrial revolution not only brings about technological change but also social transformation. The role of workers is evolving – increasingly, analytical skills, digital competencies, flexibility, and a readiness for continuous learning are valued.

Professions related to data analysis, cybersecurity, robot programming, and technological project management will gain in importance. At the same time, automated positions related to repetitive physical and administrative tasks will be phased out.

Therefore, companies are already investing not only in machines but also in people – fostering a culture of innovation and supporting the development of future competencies.

Directions for Further Digitalization of Industry

In the next stages of Industry 4.0's development, we can expect:

In Summary

Industry 4.0 is not a passing trend but a strategic direction for the development of modern economies. The fourth industrial revolution is redefining how companies design, produce, and manage. Its foundation is data, intelligent technologies, and system integration, which – when properly implemented – become sources of real competitive advantages.

Implementing Industry 4.0 solutions allows companies to not only increase efficiency and quality but also better respond to market needs, optimize costs, and build more flexible business models. In an era of increasing competition and rapid technological change, digital transformation is becoming not just an option but a necessity.

Companies that decide to take this step today will be the ones setting the standards tomorrow – not following them. Therefore, it is worth considering investing in modern technologies, employee competencies, and building a culture of innovation that will drive long-term growth.

Also see: Industry 4.0 in Poland – Implementations, Challenges, and Available Support for Companies

Want to Implement Industry 4.0 Solutions in Your Company?

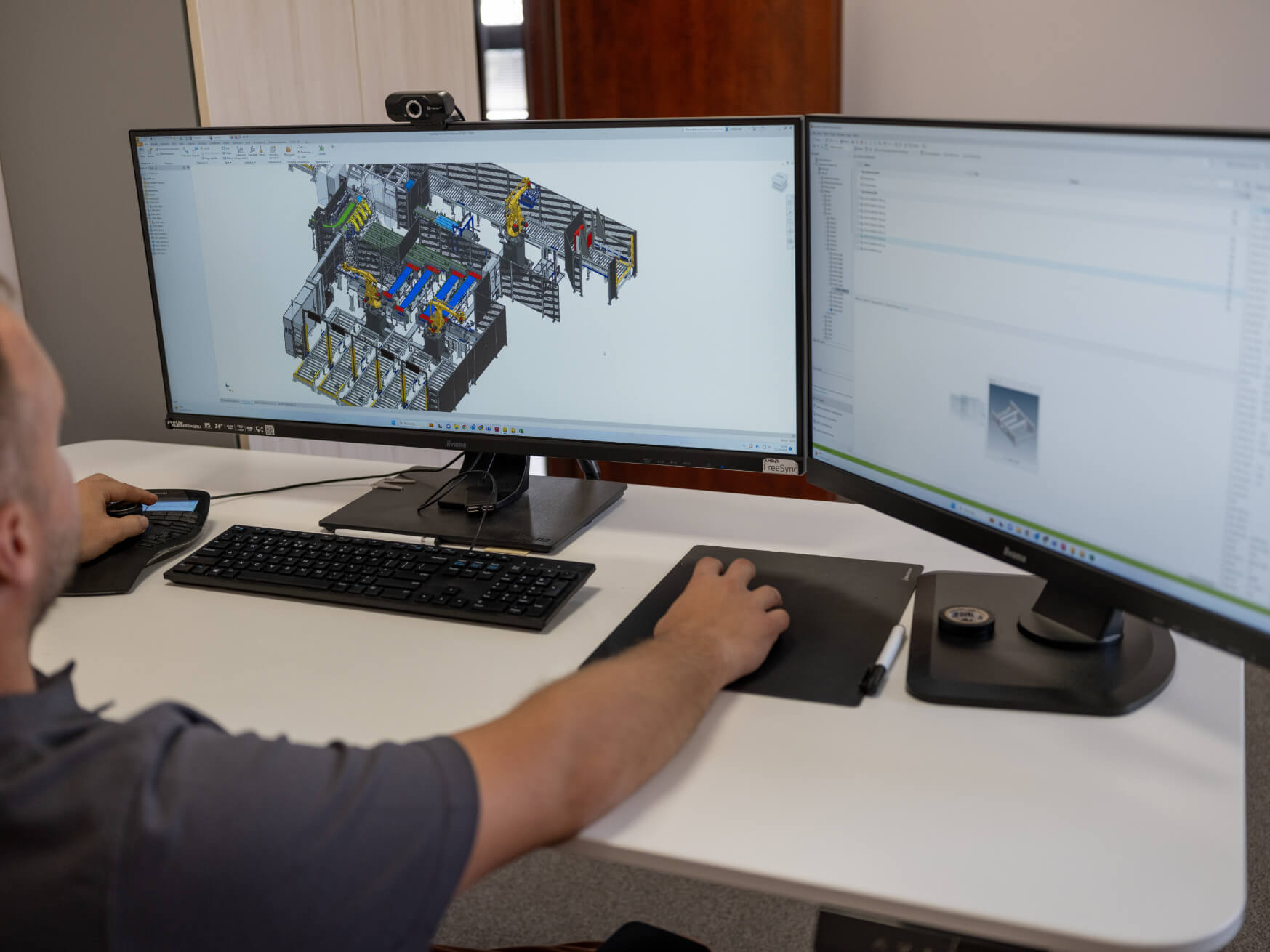

If you see that the time for real transformation has come – not just watching changes happen – it's worth choosing proven support. At Hitmark Robotics, we help companies move from idea to implementation – whether it's cobots, production automation, or better utilization of data.

Trust experts who have already helped many businesses build modern work environments where technology supports people rather than replacing them. Let's talk about what Industry 4.0 can look like in your company – in practice, not just on paper. And get ready with us for the opportunities and support the Industry 5.0 program, planned for next year, can bring to your company. Send us a message, and we'll contact you soon!