Although Industry 4.0 is often associated with solutions used by global corporations, digital transformation is also gaining momentum in Polish enterprises. More and more companies, including SMEs, are turning to automation, robotics, and advanced data analytics, supported by government and EU programs. In this section, we take a look at the current state of implementations in Poland, the initiatives supporting digitalization, and the challenges faced by entrepreneurs.

Also see: Examples of Industry 4.0 implementations and directions for its further development.

Although Industry 4.0 is mainly linked to global tech giants, an increasing number of Polish companies are adopting digital solutions, automation, and intelligent production systems. The pace of implementation in Poland is gradually increasing, with support from public administration and development institutions fostering digital transformation, especially in the SME sector.

State of Industry 4.0 Implementations in Poland

According to reports such as the "Industry 4.0 Status in Poland 2024" (prepared by APA Group), as many as 88% of companies declare that Industry 4.0 technologies have a positive impact on their competitiveness. However, many enterprises still operate without a clear strategy for implementing new technologies, and challenges remain in terms of costs and the lack of skilled specialists.

In 2020, according to data from the Open Innovation Network, 7.2% of companies had implemented future industry technologies, and 25.5% planned to start their digital transformation soon. This shows that awareness among entrepreneurs is growing, although actual implementations are progressing gradually.

Government Initiatives and Support for Companies

The Polish Agency for Enterprise Development (PARP) has been running programs for several years to support production digitalization, including "Industry 4.0," "Digitalization Voucher," and "Automation and Robotics in SMEs." These programs offer consulting, funding for investments in new technologies, and support in preparing digital transformation roadmaps.

Additionally, the Ministry of Development and Technology promotes digital transformation in industry through strategic initiatives such as the National Intelligent Specialization and sector partnerships with universities and research centers.

Examples of Implementations in Polish Companies

The Polish market has several companies successfully implementing Industry 4.0 solutions. For example:

These actions show that Industry 4.0 implementation is not reserved exclusively for large corporations – medium and smaller companies can also successfully utilize modern technologies to build their competitive advantage.

Get in touch!

If you are considering implementing modern solutions in your company – especially in the area of production process robotics – it is worth consulting experts who understand the realities of Polish industry and can tailor technology to your business goals.

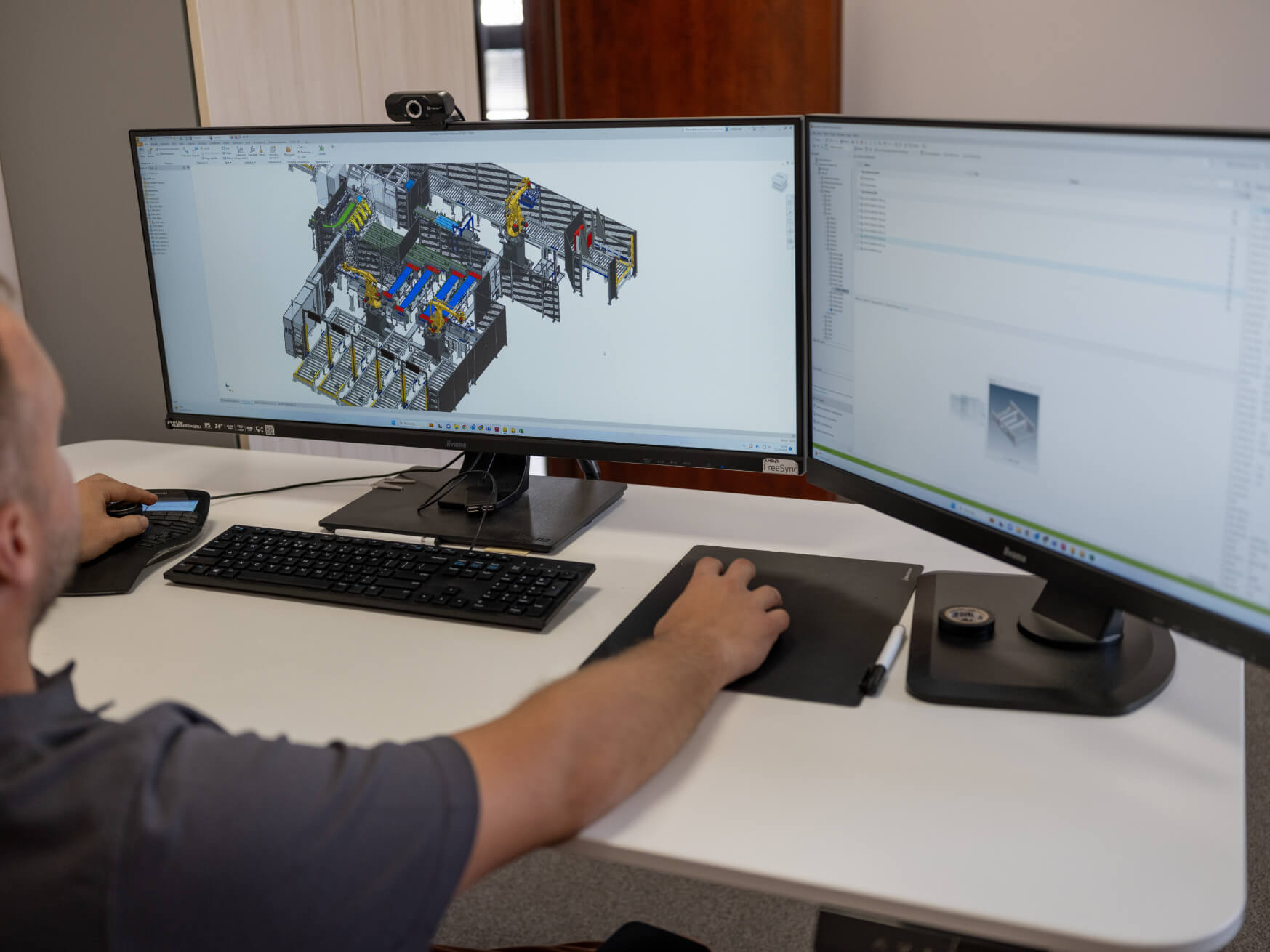

The Hitmark Robotics team supports companies in transitioning to the Industry 5.0 model. We help plan and implement collaborative robots (cobots) that enhance efficiency, improve safety, and align with the principles of sustainable, human-centered production.

Contact us to learn how robotics can truly support the growth of your company – including through available support programs.