Mixing products in boxes has become a standard in large retail chains, responding to the growing demands for efficiency and fast service. Instead of manually creating flavor sets or product types by employees, manufacturers provide ready-made boxes that can be directly placed on shelves. This solution saves time for store staff by minimizing the need for unpacking and organizing products. As a result, goods reach customers more quickly, which is crucial for the sale of products with shorter shelf lives, such as food and beverages.

The introduction of product mixing in boxes also allows for better store space management. Ready-made display boxes, which are placed directly on shelves, take up less space and enable more efficient use of sales floor space. This means that more products can be available at one time, positively impacting customer satisfaction, as they will find a wider variety of products. The requirement for product mixing in boxes is also driven by the growing expectations of consumers, who value convenience and speed in shopping – customers can easily find a variety of product options in one place without having to search through the entire shelf.

Furthermore, standardizing this process promotes more sustainable human resource management. Reducing the need for manual sorting of products allows store staff to focus on other important tasks, such as customer service or ensuring the correct product display. In this way, mixing products in boxes not only increases efficiency but also supports the overall organization of work in stores, leading to a better shopping experience and higher sales results.

Logistics in large retail chains is a complex process that requires precise coordination between manufacturers, distribution centers, and stores. When it comes to product packaging, it is crucial to adapt packaging to the expectations of the chains, which often require product variety in one package. Mixing products in boxes simplifies this process, allowing for the delivery of ready-made sets to warehouses and stores. This reduces the number of sorting errors and decreases the risk of delays in deliveries. Logistics in retail chains is also challenged by the optimization of warehouse space, so boxes containing different products in one package allow for better use of transport and storage space.

Another important aspect is the speed of order fulfillment. In times when customers expect immediate product availability, retail chains must be prepared for dynamic changes in demand. Mixing products in boxes allows for quick responses to changing needs by delivering exactly the sets that are most in demand at a given moment. This results in products reaching the shelves faster, giving retail chains an advantage over competitors who may struggle to quickly adapt their offerings.

Additionally, logistics in large retail chains must take into account aspects related to product safety during transport. When packaging products in boxes, it is important to ensure proper securing of goods to avoid damage and loss. Ready-made product mixes in boxes not only facilitate warehouse processes but also reduce the need for additional product protection during transport. This translates into lower costs associated with claims and product damages, which, in the long run, allows companies to manage their operational budget more efficiently.

Product packaging in boxes is a process that involves many factors, such as packaging dimensions, material durability, and the way products are displayed on shelves. For suppliers, it is essential to prepare boxes that meet the requirements of retail chains while being easy to identify and arrange in the store. By mixing products on pallets, stores can quickly receive deliveries that are immediately ready for display. This accelerates product rotation on shelves and allows for a better response to changing customer preferences. For suppliers, this means fewer complaints and greater satisfaction with cooperation with retail chains, leading to long-term business benefits.

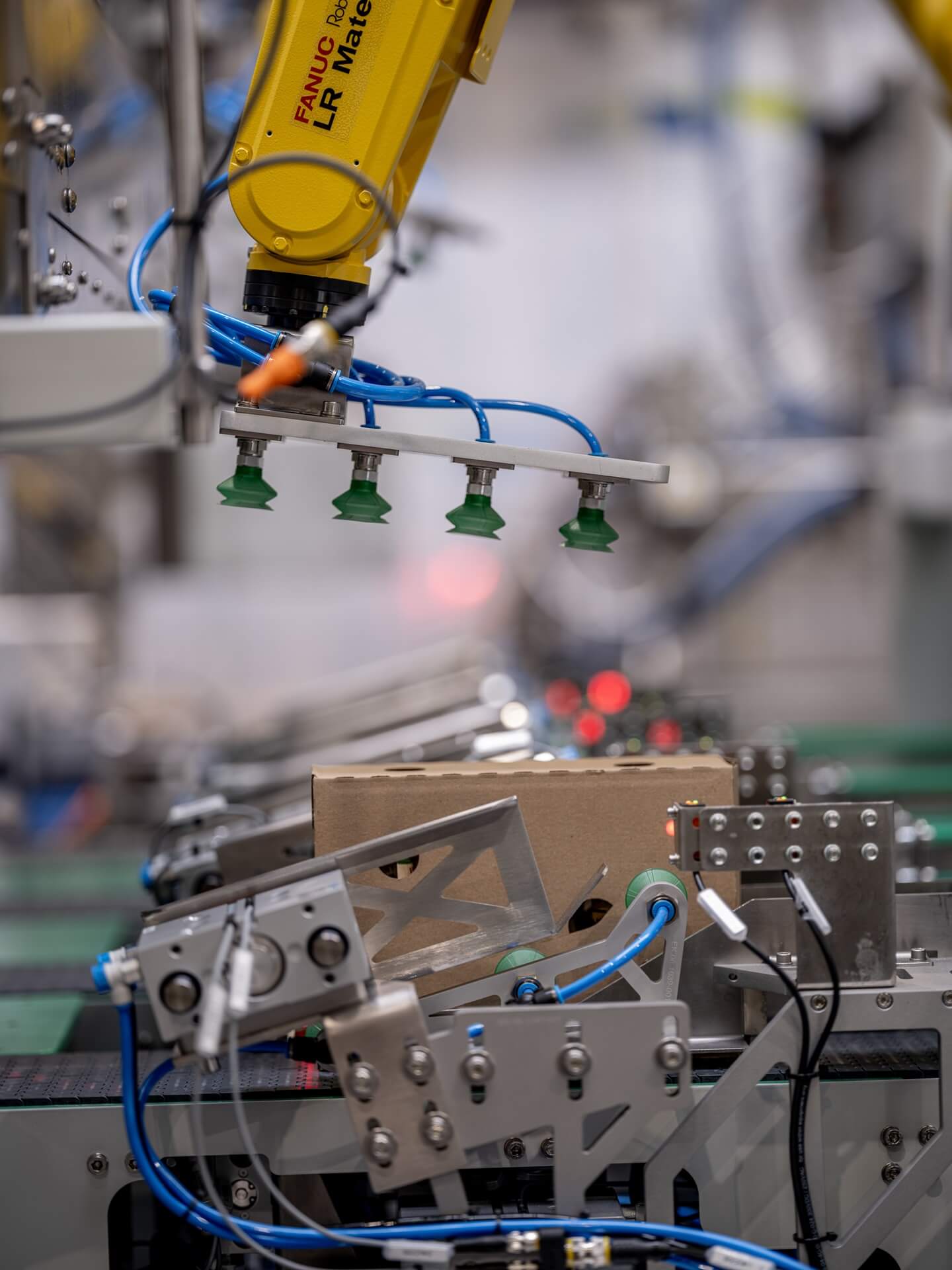

Automation of goods mixing plays an important role here, increasing the efficiency of the entire process. The use of modern technologies, such as robots, allows for precise and quick creation of product mixes in boxes, eliminating errors that often occur with manual packing. Automated systems can match different products to one box, taking into account both the requirements of retail chains and the preferences of end customers. As a result, mixing products on pallets becomes more predictable, and suppliers can easily adapt to seasonal market needs, which is crucial in a dynamic retail environment.

Moreover, automation allows for strict quality control, which is particularly important in the product packaging process. Each batch can be continuously monitored for compliance with guidelines, minimizing the risk of errors and complaints. This, in turn, increases the trust of large retail chains in suppliers, which can translate into stable and long-term business relationships. Investing in the automation of goods mixing is not only a way to improve efficiency but also to reduce waste and adopt a more sustainable approach to production, which is increasingly valued by business partners and consumers.

By combining modern technologies and optimized logistics processes, suppliers can not only meet market demands but also gain a competitive advantage by delivering products that meet the expectations of both retail chains and customers.