In today’s food industry, pouch packaging has gained immense popularity due to its versatility and functionality. This modern solution allows for the effective storage of both liquid and semi-liquid products, such as mousses or concentrates. Thanks to their flexible structure, pouches perfectly adapt to various shapes and sizes of products, making storage and transportation easier. Furthermore, pouches are highly resistant to external factors, helping maintain the quality of the products inside.

An additional advantage of pouches is their lightweight nature, which directly reduces transport costs. The reduced weight of the packaging leads to lower logistics expenses, providing financial benefits for manufacturers. Moreover, the use of pouches facilitates the recycling process, fitting well into the growing eco-friendly trend, particularly important for environmentally-conscious consumers. Pouches are easy to empty, minimizing product waste, and their innovative design allows for the creation of multi-layered packaging materials that effectively protect contents from losing nutritional value and flavor. This makes pouches a popular choice among producers and consumers, who appreciate both practicality and modern design.

Pouch packaging for mousses is a solution that has gained recognition among food manufacturers due to its numerous advantages. Primarily, they enable precise portioning of products, which is crucial for baby food, snacks, or desserts. With convenient closures, consumers can easily use the product, enhancing their satisfaction and brand loyalty. Furthermore, pouches help reduce waste as their lightweight design requires fewer materials compared to traditional jars or bottles. This, in turn, positively impacts the perception of the brand as environmentally responsible.

One of the greatest benefits of pouches for mousses is their ability to easily create innovative products that stand out on store shelves. Pouches allow for the introduction of various shapes and colors, increasing the product’s appeal to consumers. Additionally, their compact size makes them perfect for selling in sets or as samples, which is an excellent way to attract new customers. Pouches are also more practical for everyday use, as their small size makes them easy to carry on the go, meeting the needs of today’s fast-paced consumers. These features enable manufacturers to successfully compete in the market by offering convenient and aesthetically pleasing solutions that meet the expectations of increasingly demanding customers.

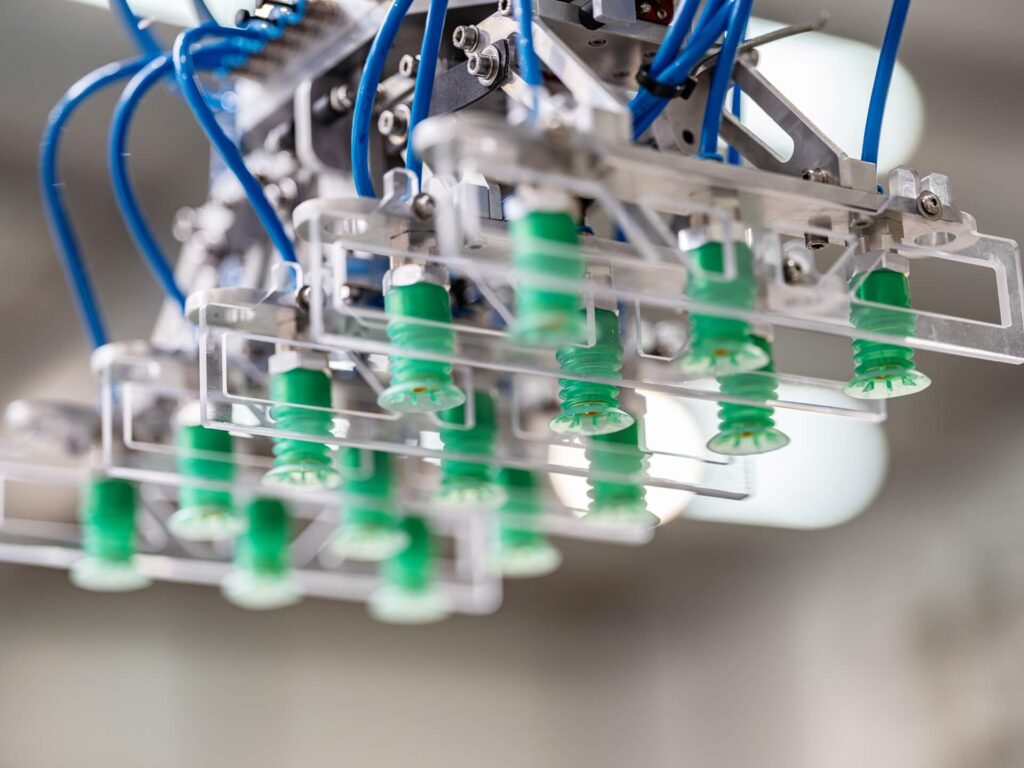

Packaging concentrates in pouches requires a precise approach to ensure the highest product quality and freshness. In this case, the correct selection of packaging material and packaging technology is key. With proper sealing and barrier properties of the materials, concentrates maintain their taste and nutritional qualities for an extended period. Additionally, the use of modern methods, such as FANUC robots for packaging, enables the automation of the process, minimizing the risk of errors and speeding up production. This not only increases the efficiency of the production line but also ensures that the final product is safe and complies with quality standards.

Modern FANUC robots for packaging not only speed up production but also ensure precision, which is essential when packaging delicate concentrates. Thanks to advanced control systems, each pouch is filled with the precise amount of product, eliminating the issue of overfilling or underfilling. This is important both from a production cost perspective and from the viewpoint of customer satisfaction, as consumers expect consistent quality. Moreover, automated packaging lines using FANUC robots can easily be adapted to changing market requirements, enabling quick product launches without the need for significant infrastructure investment. As a result, manufacturers can quickly respond to consumer demands while maintaining high quality and freshness standards.

Choosing pouches as packaging for liquid and semi-liquid products offers numerous benefits appreciated by both manufacturers and consumers. The automation of pouch packaging allows for fast and seamless production, resulting in lower costs and increased efficiency. This enables manufacturers to deliver fresh and safe products to consumers in less time. Furthermore, the flexibility of pouches allows for the creation of packaging in various sizes, catering to a wide range of consumers – from single-use portions to larger family-sized packages. This solution is also more environmentally friendly, which has become an important factor in purchasing decisions today.

One of the key advantages of pouches is their ability to ensure long-lasting freshness and quality of the product. Thanks to proper sealing and high airtightness, they protect contents from air and moisture, which is crucial for products sensitive to oxidation. Such packaging is also convenient for consumers who appreciate easy opening and closing, minimizing the risk of spills or spoilage after opening. Additionally, FANUC robots for packaging ensure precise filling and sealing of pouches, ensuring consistency in quality across every batch.

Automated pouch packaging also makes the process more sustainable, as it reduces energy consumption and waste. With modern production lines, manufacturers can optimize operational costs while offering products packed in a way that aligns with consumer needs and lifestyles. All these factors contribute to the growing popularity of pouches as an excellent combination of functionality, aesthetics, and efficiency.