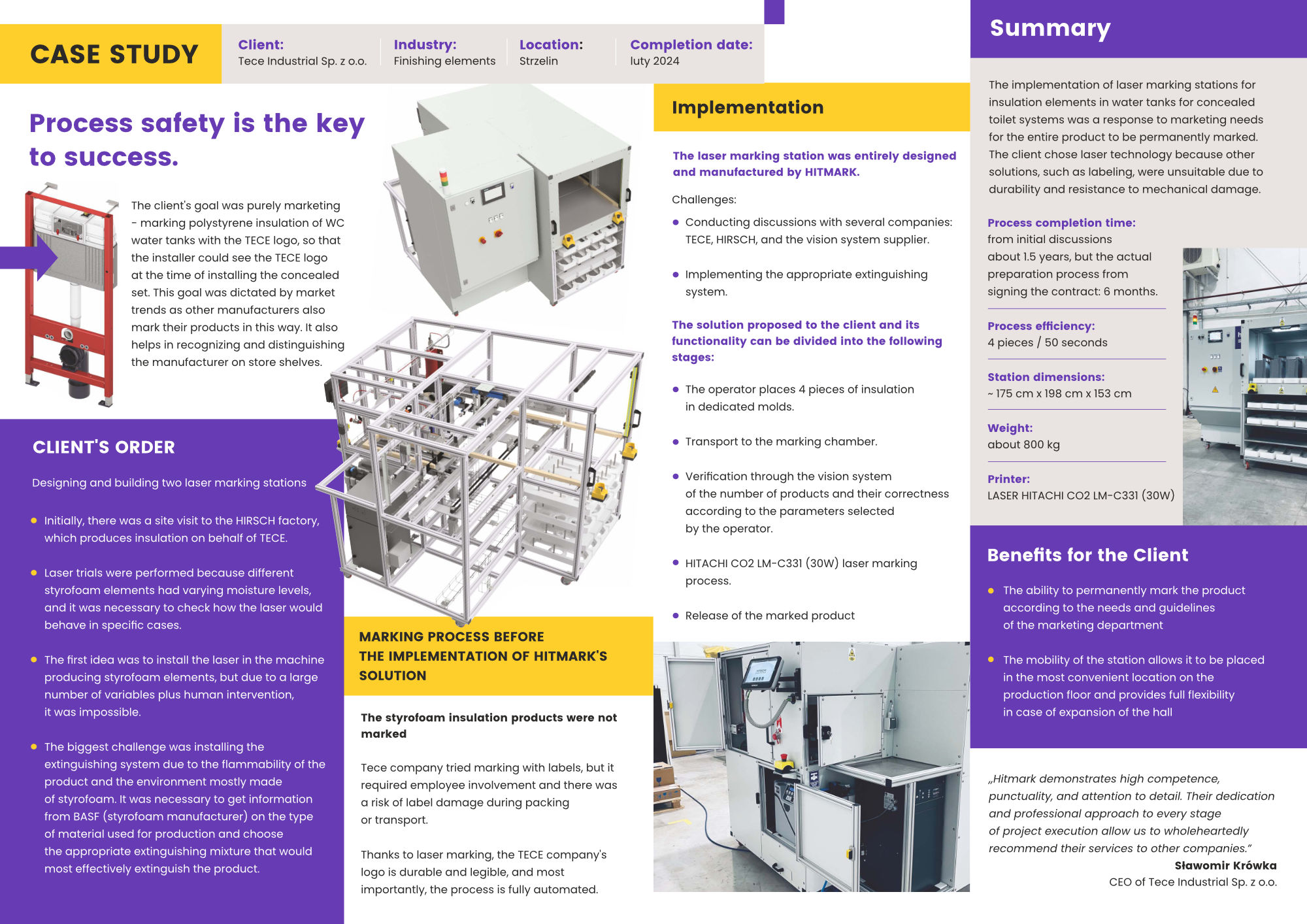

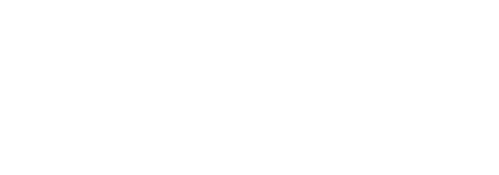

Previously handled manually with labels, the process now uses the Hitachi LM-C331 laser to mark four products simultaneously. With integrated vision control, each product is marked according to operator-selected parameters, ensuring precision and reducing labor needs.